Candlemaking

Practical Action

Candle dyes are available in solid blocks or as powder which can be directly added to the wax as it

is melting. A wide range of colours are available and suppliers will provide information concerning

quantities required, as this will vary depending upon the concentration of the dyes. It is advisable

to mix small test samples of colour before producing candles, particularly since some colours tend

to change as they cool. Some dyed candles will have a tendency to fade over time, especially if left

in strong light.

Scented candles are now a well established and popular product. Some countries have suppliers

offering scents specifically designed for candles. These are liquids that are added to the melted

wax during production. The result is a scented candle which usually releases more fragrance when

it is lit. The degree to which the scent is released from the wax is known as the ‘throw’. Essential

oils can also be used as scents for candles and other locally available natural fragrances can be

experimented with.

Heating methods

Safety

When heating wax it is very important to be aware of some essential safety precautions.

It is important that wax is not overheated. At high temperatures (usually above about 150°C) wax

will start to smoke and give off unpleasant and dangerous fumes. At a higher temperature wax will

reach its ‘flash point’ and can spontaneously ignite. An open flame will also ignite liquid wax.

Once burning, liquid wax is difficult to extinguish and can cause a serious fire. If a fire does start,

the heat source should be tuned off immediately and if possible the burning wax should be staved

of air (oxygen) by covering with a metal lid or a damp cloth. On no account try to extinguish

burning wax with water as it will intensify the fire.

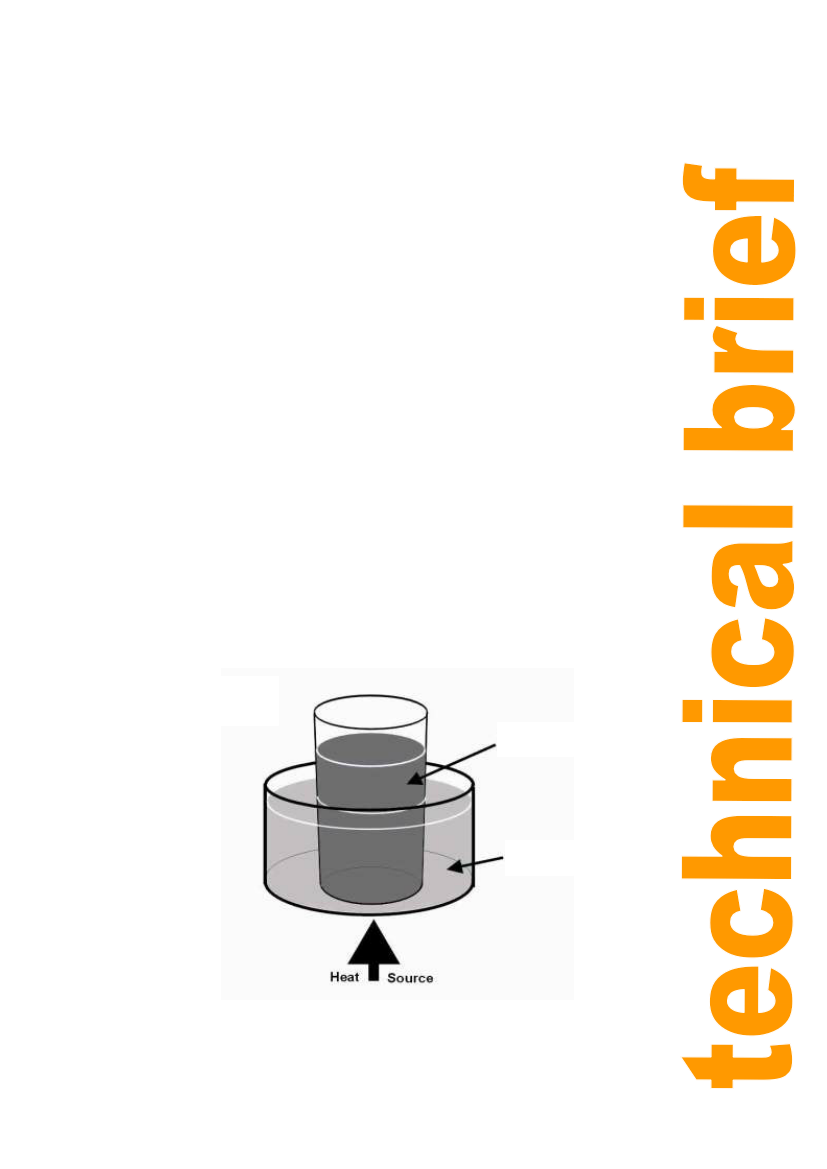

The chances of overheating can be greatly reduced if the wax melting pot is not heated directly. To

do this, the melting pot can be placed into a larger container of hot water and the wax heated by

the surrounding water. This is known as a double boiler (figure 2). Even with this method, always

make sure that the water does not boil away.

Figure 2:

Double boiler

Wax

Water

3